High quality metal precision CNC milling processing anodized parts

services

How does CNC milling work?

Milling is a subtractive manufacturing process where the tool

enters the clamping material at a higher speed and a specified feed

rate. Modern CNC milling machines gradually remove material from

blocks, plates, or rods using milling heads to shape workpieces.

CNC milling machines use rotary cutting tools to mechanically

whittle away material to achieve the desired part design. Depending

on the number of axes of the CNC milling machine, the more complex

the final CNC milling part can be.

By incorporating anodizing into your manufacturing process, you can

produce components that not only look great but also perform well

in a variety of applications. If you want your CNC machining

project to be robust and durable, anodizing is a necessary step.

The Importance of an Anodized Finish

Enhanced Durability |

Our anodized finishes significantly increase the durability and

lifespan of aluminum parts. The hard, wear-resistant surface

provided by the anodic oxide layer improves resistance to abrasion,

scratches, and wear, ensuring that your components maintain their

integrity and appearance over time.

|

Boosted Corrosion Resistance |

One of the primary advantages of our anodized finishes is their

superior resistance to corrosion. This makes anodized aluminum

ideal for applications exposed to harsh conditions or outdoor

environments.

|

Electrical Insulation |

Our anodized finishes provide electrical insulation properties,

making them ideal for applications where electrical conductivity

needs to be minimized or controlled.This is especially beneficial

in automotive components and electrical enclosures.

|

The following are sectors where anodized aluminum are best used:

- Aerospace: Anodized aluminum is commonly used in aircraft

components, structural components and internal accessories.

- Consumer goods: Sports equipment, appliances and jewelry can all

use anodized aluminum.

- Automotive: Anodized aluminum can be used in many automotive

components, including trim, trim and engine parts.

Metal anodizing is a popular technique in the engineering and

manufacturer communities. It is known for improving the strength,

durability and service life of mechanical components, making it an

important technology in the manufacturing process. In addition to

these advantages, anodizing has several advantages that make it

important for producing high-quality parts.

Aterials for CNC Milling Parts

Depending on your applications, our CNC milling process is

compatible with an extensive range of materials.

We stock over 30 production-grade metal alloys for producing

various CNC milled parts for different industries.

| Aluminum |

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

| Tolerances |

| Copper |

Copper displays excellent thermal conductivity, electrical

conductivity and plasticity. It is also highly ductile, corrosion

resistant and can be easily welded.

| ±0.125mm (±0.005″) |

| Stainless Steel |

Stainless steel is the low carbon steel that offers many properties

that are sought after for industrial applications. Stainless steel

typically contains a minimum of 10% chromium by weight.

| ±0.125mm (±0.005″) |

| Titanium |

Titanium has a number of material properties that make it the ideal

metal for demanding applications. These properties include

excellent resistance to corrosion, chemicals and extreme

temperatures.

| ±0.125mm (±0.005″) |

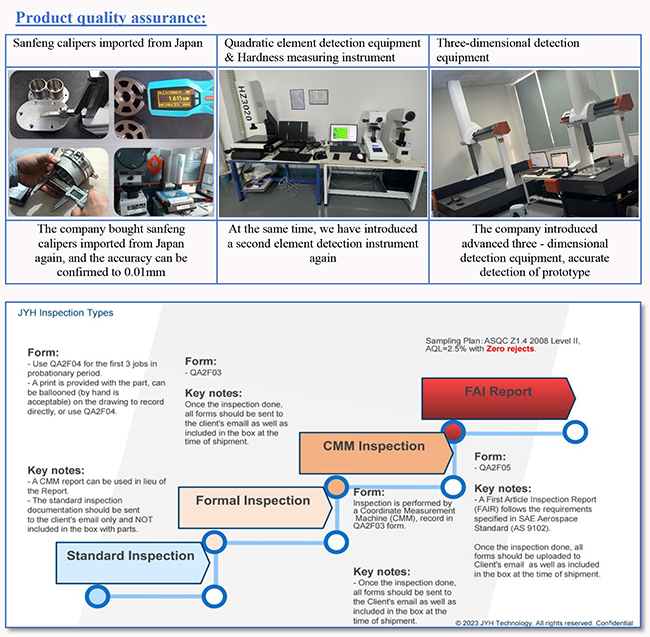

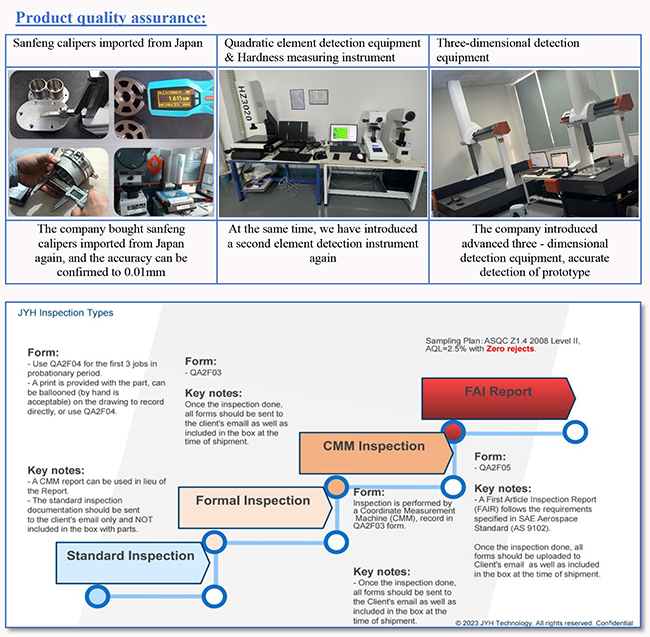

Our quality endure system

Our workshop

JYH can provide you with the most appropriate solution to your part

design, material selection, and surface finishing options