UAV Parts Magnesium Precision Machining CNC Parts for Aerospace

Industry

We can provide Precise Tolerance with +/- 0.001mm and JYH's

Machining Magnesium Alloy service is a good choice for high

quality, ISO 9001 :2015 certified products.

JYH Manufacturing Capabilities

We have 60 CNC machining centers, 10 CNC lathes, 5 CNC longitudinal

lathes, slow-speed wire cutting machines and so on, providing much

manufacturing flexibility. Our engineers select the ideal equipment

for an application based on the geometry, material, and volume of

the part being machined to provide customers with premium quality

parts at the good price.

Application Range:

Car engine accessory bracket, Clutch housing, Gearbox housing,

Instrument panel frame, Steering wheel frame phone,Drone

UAV/Camera.Magnesium alloy is very suitable for this kind of

product because it is very light.

Available material

| Material Type | Tensile Strength | Elongation | Yield Stress | Density | Maximum Temperature | Tensile Modulus |

| AZ91D | 230MPa | 3.0% | 150MPa | 1.81g/㎤ | 595℃ | 44.8GPa |

| AZ80A | 290MPa | 2.0~5.0% | 179MPa | 1.81g/㎤ | 595℃ | 45Gpa |

| AZ31B | 280MPa | 8% | 160MPa | 1.76g/㎤ | 595℃ | 46GPa |

| ZK61B | 330Mpa | 12% | 178MPa | 1.81g/㎤ | 630℃ | 47GPa |

| AZ61B | 280Mpa | 14% | 165Mpa | 1.81g/㎤ | 653℃ | 45GPa |

| AM60B | 221MPa | 4.0% | 131Mpa | 1.81g/㎤ | 428℃ | 44.8GPa |

| WE43 | 225MPa | 14% | 165Mpa | 1.81g/㎤ | 630℃ | 48GPa |

| QE22 | 280MPa | 2.0~4.0% | 170MPa | 1.72g/㎤ | 565℃ | 47GPa |

The Characteristics of Magnesium Parts Can be as follows:

- CNC machining magnesium product have high strength, the ratio of

strength to quality of magnesium alloy has a capacity.

- Magnesium parts have small elastic modulus, good rigidity, strong

shock resistance, and are not easily deformed after long-term use.

- Magnesium machining product have good resistance to electromagnetic

interference and shielding.

Type of Magnesium Parts | Tolerance of Magnesium Parts |

Linear dimension

| +/- 0.015 mm

+/- 0.002 inch

|

| Hole diameters (not reamed) | +/- 0.015 mm

+/- 0.002 inch

|

| Shaft diameters | +/- 0.015 mm

+/- 0.002 inch

|

| Part size's limit | 850 * 650 *550 mm

39.0 * 23.5 * 23.5 inch |

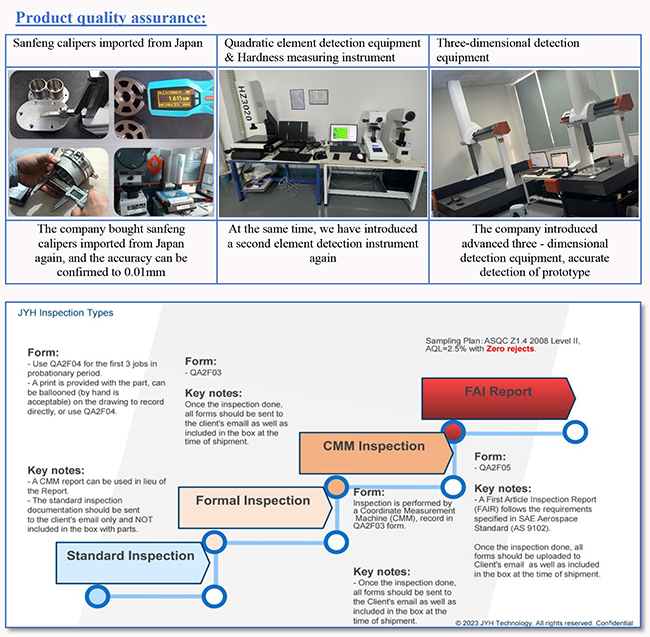

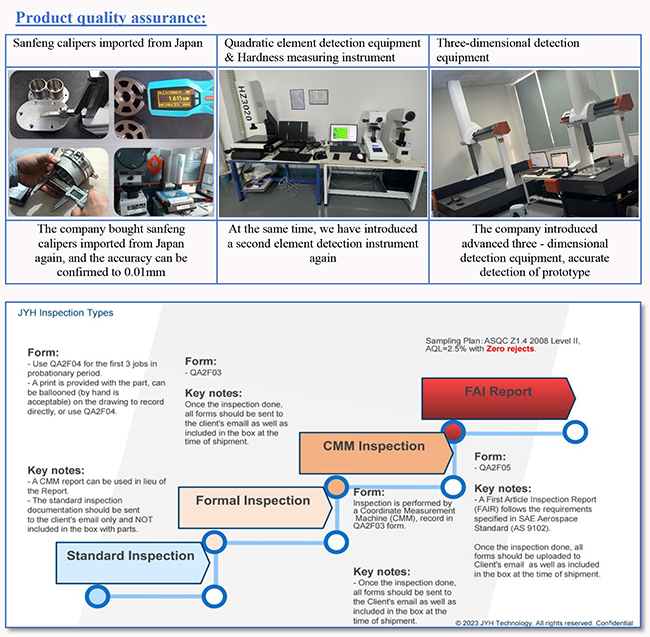

Quality Inspection

- In addition to our stringent in-process controls, all components

must pass a thorough final inspection.

we have a coordinate measuring machine, salt spray testing

machines, profile projectors and other precision

measuring devices, etc.

- Customers' CAD drawings can be directly imported in the coordinate

measuring machines (CMM) for a

direct comparison to the dimensions that are taken from the

physical part.

- All testing is conducted in a 20 degree Celsius climate-controlled

inspection room and the CMM is calibrated to

GB/T 16857.2-2006 (ISO10360-2:2001) standards. All components and

sub-assemblies are 100% inspected,

identified with a logo if required and a final inspection is

generated pertaining to all the critical dimensions.

Our payment method

Our shipping method

Advantages And Challenges Of CNC Machining?

Accuracy and precision:

CNC machines are highly accurate and can consistently produce parts

with tight tolerances.

This level of precision is difficult to achieve with manual

machining processes.

Repeatability:

CNC machines can produce identical parts over and over again with

the same high level of accuracy and precision.

This makes CNC machining ideal for large-scale production runs.

Machining Speed:

CNC machines can produce parts quickly and efficiently, especially

when compared to manual machining processes.

This allows for faster turnaround times and shorter production

cycles.

Flexibility:

CNC machines can be programmed to produce a wide range of parts and

can handle a variety of materials, including metals,

plastics, and composites.

Reduced costs:

Because CNC machines are automated, they require less human

intervention than manual machines.

This means that fewer workers are needed to operate and monitor the

machines, which can result in lower labor costs.

Our workshop

FAQ:

1-Is magnesium hard to machine? - Drilling, milling, turning, and other processes are smoother when

using magnesium, and machining the material requires a

significantly lower cutting force and overall production time than

other metals.

|

2-Can you CNC magnesium? - Magnesium is a lightweight metal with high level of machining

ability that can be CNC machined to create parts with high strength

and excellent corrosion resistance. However, magnesium can be

difficult to machine due to its tendency to ignite or explode if

proper precautions are not taken

|

3-How many machines do you have? - We currently have more than 60 machines: roughly 40+ CNC mills and

30 Injection mold machine,10+ 3D printers. With our long history of

growth, this number is always changing.

|

4-How do I get a quote? - To get a quote for all of our services, simply send us your 3D CAD

model to us. You'll get an interactive quote within hours with free

design feedback. If there are problem areas in the submitted

design,we will provide free design feedback(DFM).

|

5-What types of files do you accept? - We can accept native SolidWorks or ProE files as well as solid 3D

CAD models from other CAD systems output in IGES (.igs), STEP

(.stp), ACIS (.sat) or Parasolid (.x_t or .x_b) format.

|

6-Do you provide First Article of Inspection (FAI) Service? - We can provide FAI as part of the unlimited offer.

|

7-What is payment term does your company can be acceptable? - We can accept T/T (50 prepayment should be paid before start the

production; the 50% remaining payment should be paid after finish

the project).

|

Magnesium Sample Pictures for your reference:

JYH technology, Your Professional CNC Machining Magnesium Alloy

Services Partner!