Stainless steel alloy CNC machining has a wide range of

applications in many fields.

The following are some common stainless steel CNC machining

applications:

1.Manufacturing: Stainless steel alloy is widely used in the manufacturing

industry. Through CNC machining,

various stainless steel parts and components can be manufactured,

such as mechanical parts, connectors, fixtures,

bearing housings, etc. Stainless steel's corrosion resistance, high

strength and wear resistance make it a

commonly used material in manufacturing.

2.Medical devices: Stainless steel also has important applications in the manufacture

of medical devices.

Through CNC machining, surgical instruments, implantable

instruments, medical equipment enclosures

can be manufactured. Stainless steel's corrosion resistance, high

strength and biocompatibility make it ideal for

medical device manufacturing.

3.Automotive industry: The application of stainless steel in automotive manufacturing is

also gradually increasing.

Through CNC machining, auto parts can be manufactured, such as

exhaust pipes, intake pipes, body structural parts, etc.

Stainless steel's corrosion resistance, high strength and

lightweight properties make it an ideal material in the automotive

industry.

4.Aerospace industry: The application of stainless steel in the aerospace field has also

increased.

Through CNC machining, aerospace parts can be manufactured, such as

engine parts, structural parts and so on.

Stainless steel's high strength, corrosion resistance and high

temperature stability make it suitable for harsh environments

in the aerospace sector.

Advantages and Benefits of Steel CNC Machining:

- Certified Excellence: JYH Machining company already Pass ISO9001 certification and an

import/export license, we validate our dedication to quality,

standards, and global operations

|

- Rapid Turnaround:JYH produces highly accurate, quick turn machined parts in as fast

as 1- 3 days.

|

- Wide Material Compatibility: CNC precision machining can work with a serie of materials,

including metals, plastics, composites, and ceramics.

|

- Precision: JYH Offers high-precision tolerances ranging from +/-0.001″ to

0.005″, depending on our customer 's needs.

|

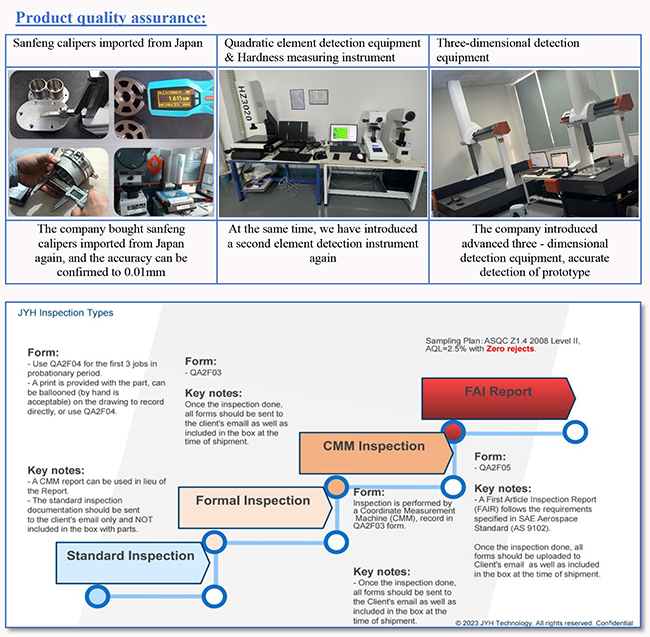

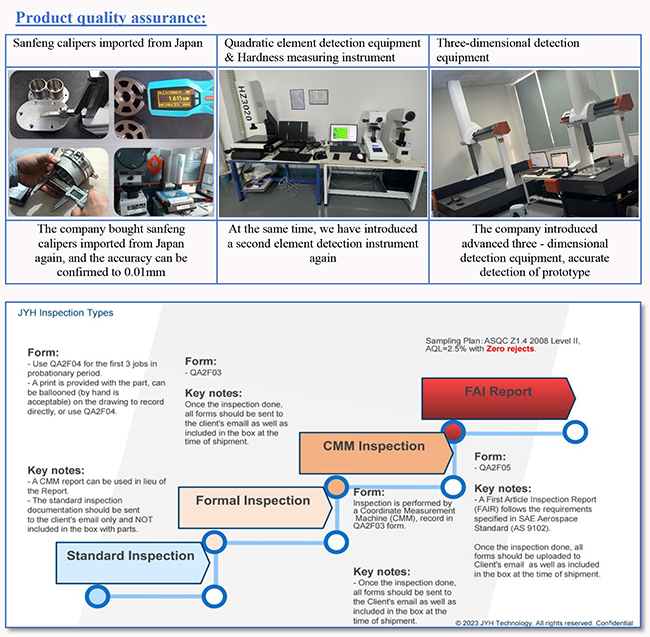

- Quality Control: CNC machines can be equipped with sensors and monitoring systems

to provide real-time feedback, increasing quality control and

identifying issues early in the process.

|

- Process Consistency:Uniform cutting speeds, feed rates, and tool paths maintain

consistent surface finishes and part dimensions throughout the

production cycle.

|

We have an ensuring Quality sysem for our clients

Payment method

Shipping way

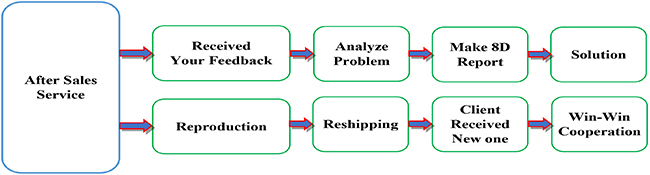

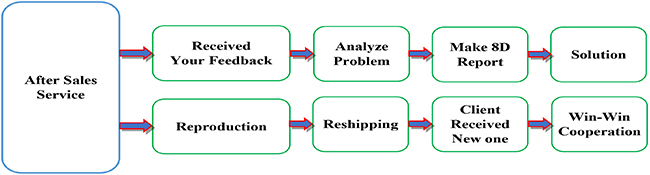

After service sales

Package way

FAQ:

1-What industries use JYH services? - We serve a variety of industries including medical device,

automotive, Robot, aerospace,consumer product.

|

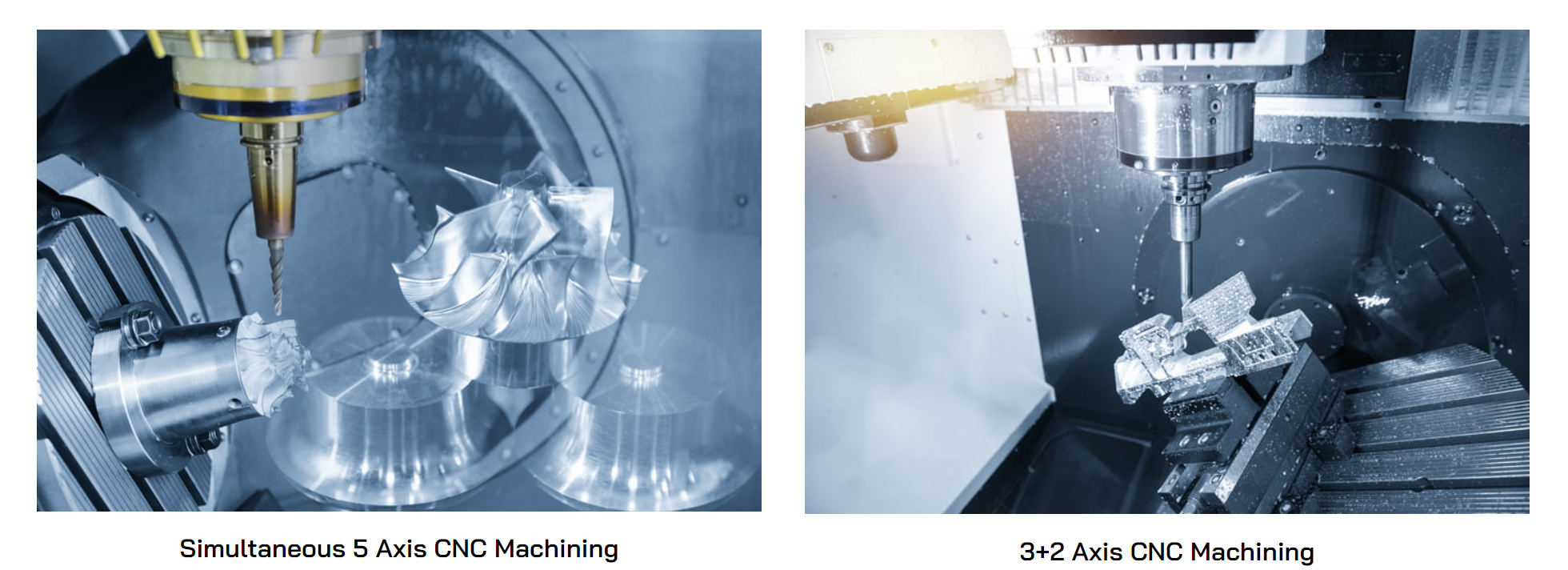

2-How many machines do you have? - We currently have more than 60 machines: roughly 40+ CNC mills and

30 Injection mold machine,10+ 3D printers. With our long history of

growth, this number is always changing.

|

3-How do I get a quote? - To get a quote for all of our services, simply send us your 3D CAD

model to us. You'll get an interactive quote within hours with free

design feedback. If there are problem areas in the submitted

design,we will provide free design feedback(DFM).

|

4-What types of files do you accept? - We can accept IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid

(.x_t or .x_b) format.

|

5-Do you provide First Article of Inspection (FAI) Service? - We can provide FAI as part of the unlimited offer.

|

6-What is payment term does your company can be acceptable? - We can accept T/T (50% prepayment should be paid before start the

production; the 50% remaining payment should be paid after finish

the project).

|

If you need custom machined parts with complex geometries, or get

end-use products in the shortest possible time,

JYH CNC Precision maching company is good enough to break through

all of that and achieve your idea immediately.