CNC Stainless Steel Parts , Custom Precision Prototype Machining

With Passivating

Stainless steel is well-suited for a wide array of CNC machining

projects, due to its excellent machinability and outstanding

uniformity.

JYH CNC Precision Machining delivers high quality precision

machining with an incredible range of manufacturing capabilities.

1.Fast quotes within half hours

2.Machined parts as fast as 1 day

3.Tolerances down to ±0.0004″ (0.01mm)

4.Free & Automatic DFM feedback

Stainless Steel Grades Chart

GRADE

| TYPE | TRAITS | USES |

| 3CR12 | Ferritic | Useful corrosion resistance, particularly in wet abrasion

environments. Readily welded and formed. | Tanks, flues, bins, chutes, rail wagons |

| 201 |

Austenitic

| Low nickel, high work hardening. | Cookware, hose clamps |

| 301 | Austenitic | Combination of strength and ductility to withstand severe forming

methods. Corrosion resistance comparable to 302. | Rail cars, automotive components |

| 302 | Austenitic | Excellent corrosion resistance. High strength and hardness. | Food and drink, sanitary, cryogenic and pressure applications |

| 303 | Austenitic | Addition of sulfur or selenium gives it best machinability of all

austenitic grades, but reduces corrosion resistance compared to

304. | Nuts and bolts, aircraft fittings and gears, bushings |

304

304L 304H | Austenitic | Slightly magnetic when cold worked. Excellent corrosion resistance

but susceptible to pitting corrosion in warm chloride environments.

Excellent toughness

Accounts for 50% of all stainless steel produced. | Architecture, kitchens, food processing |

| 309S |

Austenitic

| Resistant to oxidation. | Heating, furnace parts |

316

316L 316H | Austenitic | Same mechanical and physical properties as 304 but more resistant

to pitting corrosion, especially in warm chloride environments.

Virtually non-magnetic. | Marine architectural components, food processing, hot water systems |

| 317L | Austenitic | Improved corrosion resistance over 316. 317L is a variation of 317

suitable for heavy-gauge welding. | Pulp and paper machinery, ink and dying processes, acetic acid

distillation |

| 321 | Austenitic | Titanium-stabilized. | Aircraft, heat exchangers (up to intermediate temperatures) |

| 400 | Ferritic | Corrosion resistance comparable to 409, better surface finish | Caskets, applications requiring better finish than 409 |

| 409, Aluminized 409 | Ferritic | Resists atmospheric and automotive exhaust gas corrosion.

Aluminized version adds salt and cosmetic corrosion resistance. | Auto exhaust systems, heat exchangers, furnace liners |

| 410, 410H | Martensitic | Resists dry atmospheres, freshwater, mild alkalis and acids, steam,

and hot gases. Must harden for best heat and corrosion resistance.

410H has better hardenability. | Bolts, nuts, screws, pump parts and shafts, turbine parts, mine

ladder rungs, cutlery, rulers, cold heading |

| 420, 420HC | Martensitic | Good resistance in hardened condition to atmosphere. Higher-carbon

grade. HC offers better hardenability. | Cutlery, stainless steel hospital equipment, needle valves |

The tolerance of CNC Machining For Stainless Steel Parts

Type

| Tolerance |

Linear dimension

| +/- 0.025 mm

+/- 0.001 inch

|

| Hole diameters (not reamed) | +/- 0.025 mm

+/- 0.001 inch

|

| Shaft diameters | +/- 0.025 mm

+/- 0.001 inch

|

| Part size limit | 950 * 750 *650 mm

38.0 * 22.5 * 22.5 inch |

Advantages and Benefits of Steel CNC Machining:

- Custom Finishes: Select from a variety of finishes on metal,built to precise design

specifications.

|

- Rapid Turnaround: Using the latest in steel CNC machining and online quoting

technologies, JYH produces highly accurate, quick turn machined

parts in as fast as 1- 3 days.

|

- Material Selection: Choose from over 60 metal, Metal milling offers a variety of

certified materials.

|

- Precision: Offers high-precision tolerances ranging from +/-0.001″ – 0.005″,

depending on customer needs.

|

Stainless Steel Machining Applications

CNC machining of stainless steel is used to produce a variety of

parts in the medical industry, robotics, food and beverage

industry, aerospace, and any industry that requires high-strength

applications. Stainless steel is an ideal material for applications

such as:

-Medical instruments

-Machine parts

-Vacuum and pressure vessels

-Heavy construction equipment

-Gears

Benefits of Stainless Steel 303

-Resistant to oxidation

-Non-magnetic austenitic stainless steel

-Corrosion-resistant properties

-Designed to exhibit improved machinability

Benefits of Stainless Steel 316/316L and 304/304L

-Processed for improved machinability

-Faster machining speeds

-Corrosion resistant

-Longer tool life

-Lower total cost of machined parts

Benefits of Stainless Steel Type 360 (17-4 SS)

-Designed to exhibit improved machinability

-Superior corrosion resistance

-High strength in all conditions

-Precipitation-hardening martensitic stainless steel

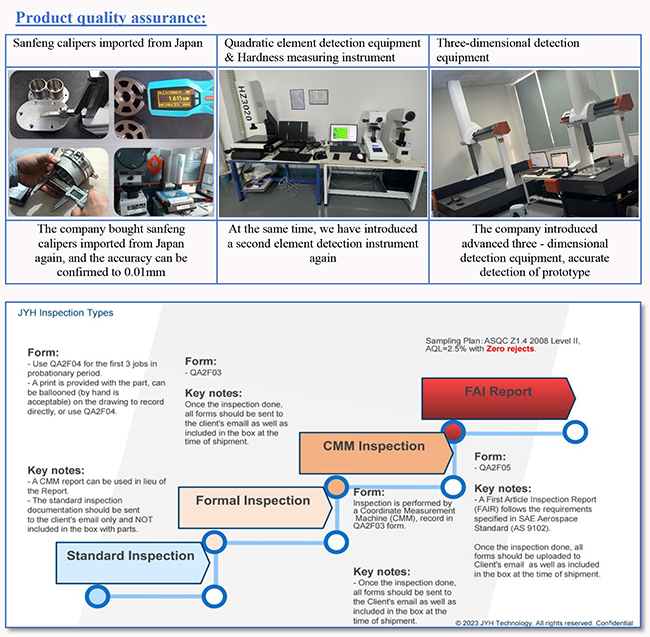

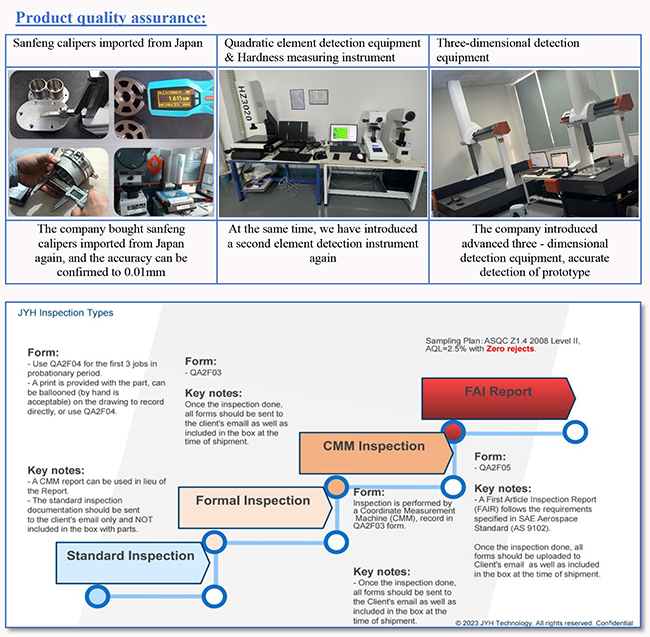

We have an ensuring Quality sysem for our clients.

Payment method

Shipping way

Package way

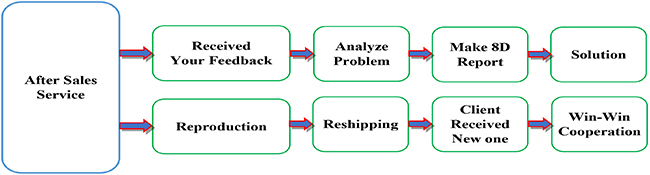

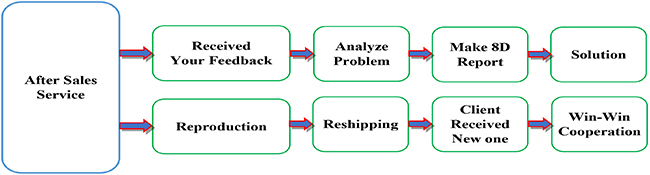

After service sales

FAQ:

1-What is the advantage of working with JYH company? Why should I

choose your company to make my parts? - Our industrial CNC machining stainless steel provide parts made

directly from the customer’s 3D drawings, reducing the likelihood

of errors. Proprietary software automates toolpath generation to

decrease manufacturing times and reduce costs.

|

2-What industries use JYH services? - We serve a variety of industries including medical device,

automotive, Robot, aerospace,consumer product.

|

3-How many machines do you have? - We currently have more than 60 machines: roughly 40+ CNC mills and

30 Injection mold machine,10+ 3D printers. With our long history of

growth, this number is always changing.

|

4-How do I get a quote? - To get a quote for all of our services, simply send us your 3D CAD

model to us. You'll get an interactive quote within hours with free

design feedback. If there are problem areas in the submitted

design,we will provide free design feedback(DFM).

|

5-What types of files do you accept? - We can accept IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid

(.x_t or .x_b) format.

|

6-Do you provide First Article of Inspection (FAI) Service? - We can provide FAI as part of the unlimited offer.

|

7-What is payment term does your company can be acceptable? - We can accept T/T (50% prepayment should be paid before start the

production; the 50% remaining payment should be paid after finish

the project).

|

8-What is your lead time after we place an order with you?

Once get your order,we will sart to order review and it is usually

takes 3-6 work days,but it should be finally to the actual product

quantity, structure, post-processing. |

CNC machining workshop

JYH technology, Your Professional CNC Machining Steel prototyping

Service Partner!