Quick Turn CNC Machining Service For Prototype And Produce

Stainless Steel Parts

JYH CNC Precision Machining delivers high quality precision

machining with an incredible range of manufacturing capabilities.

CNC precision machining is a manufacturing process that utilizes

Computer Numerical Control (CNC) technology to create highly

accurate and intricate parts and components and Stainless steel is

well-suited for a wide array of CNC machining projects, due to its

excellent machinability and outstanding uniformity.

This technology ensures tight tolerances, consistent quality, and

repeatability in the production of complex geometries, making it a

preferred method for industries such as aerospace, automotive,

electronics, and medical devices.

1.Fast quotes within half hours

2.Tolerances down to ±0.0004″ (0.01mm)

3.Free & Automatic DFM feedback

The tolerance of CNC Machining For Stainless Steel Parts

Type

| Tolerance |

Linear dimension

| +/- 0.025 mm

+/- 0.001 inch

|

| Hole diameters (not reamed) | +/- 0.025 mm

+/- 0.001 inch

|

| Shaft diameters | +/- 0.025 mm

+/- 0.001 inch

|

| Part size limit | 950 * 750 *650 mm

38.0 * 22.5 * 22.5 inch |

CNC process service flow

Compare Stainless Steel Alloys

We offer a variety of stainless steel options to suit any

specifications or requirements. Stainless Steel 304/304L and

316/316L as well as Stainless Steel 303 and Type 360 (17-4) have

all proven to be high-quality options for CNC machining projects

that

require either milling or turning.The metal has a very high tensile

strength, and has high resistance to corrosion and wear, resulting

in added product durability and part longevity.

| Material Type | Tensile Strength | Elongation | Yield Stress | Density | Tensile Modulus | Hardness |

| SS303 | 620MPa | 50% | 140MPa | 8g/㎤ | 56GPa | 95HB |

| SS304 | 500MPa | 80% | 220MPa | 8g/㎤ | 71GPa | 150HB |

| S316L | 560MPa | 55% | 300MPa | 7.8g/㎤ | 70GPa | 120HB |

| SS410 | 1470Mpa | 15% | 1000MPa | 7.8g/㎤ | 65GPa | 110HB |

| SS416 | 750Mpa | 23% | 590Mpa | 7.8g/㎤ | 60GPa | 90HB |

Stainless steel CNC machining has a wide range of applications in

many fields.

stainless steel CNC machining applications:

►Manufacturing: Stainless steel is widely used in the manufacturing industry.

Through CNC machining, various stainless steel parts and components

can be manufactured, such as mechanical parts, connectors,

fixtures, bearing housings, etc. Stainless steel's corrosion

resistance, high strength and wear resistance make it a commonly

used material in manufacturing.

►Medical devices: Stainless steel also has important applications in the manufacture

of medical devices. Through CNC machining, surgical instruments,

implantable instruments, medical equipment enclosures can be

manufactured. Stainless steel's corrosion resistance, high strength

and biocompatibility make it ideal for medical device

manufacturing.

►Automotive industry: The application of stainless steel in automotive manufacturing is

also gradually increasing. Through CNC machining, auto parts can be

manufactured, such as exhaust pipes, intake pipes, body structural

parts, etc. Stainless steel's corrosion resistance, high strength

and lightweight properties make it an ideal material in the

automotive industry.

►Aerospace industry: The application of stainless steel in the aerospace field has also

increased. Through CNC machining, aerospace parts can be

manufactured, such as engine parts, structural parts and so on.

Stainless steel's high strength, corrosion resistance and high

temperature stability make it suitable for harsh environments in

the aerospace sector.

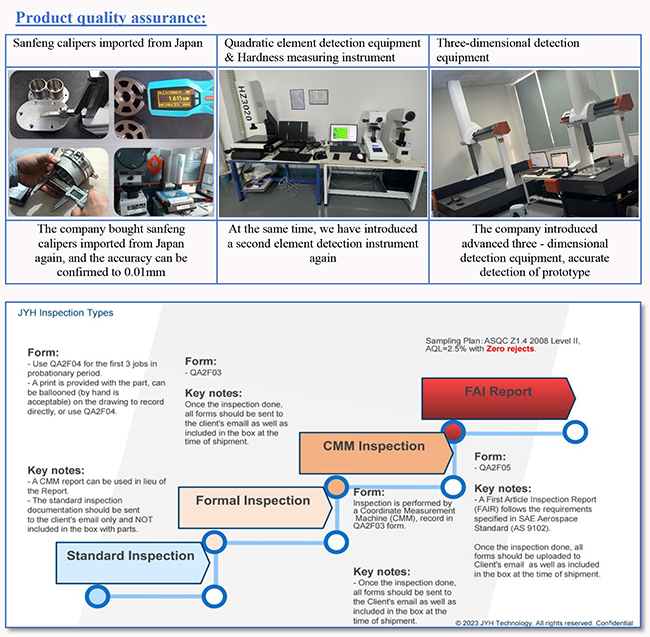

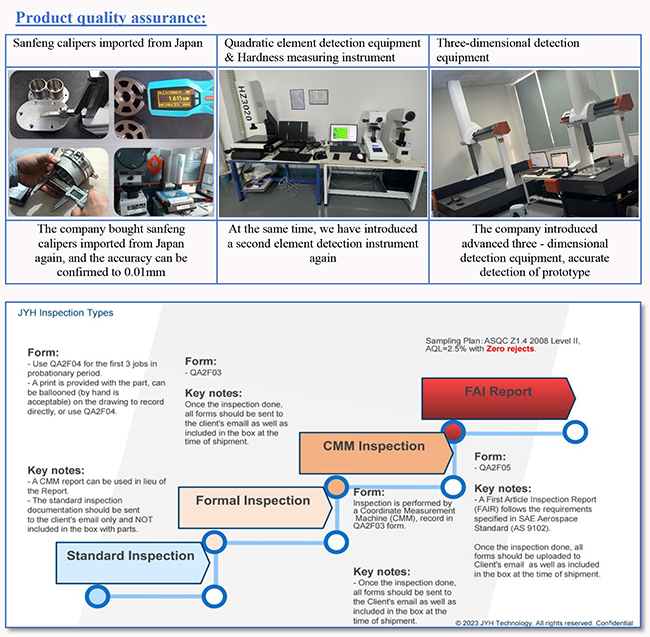

We have an ensuring Quality sysem for our clients

Payment method

Shipping way

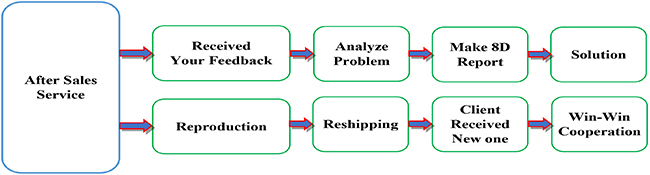

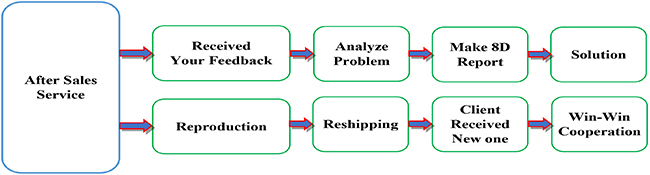

After service sales

FAQ:

1-What is the advantage of working with JYH company? Why should I

choose your company to make my parts? - Our industrial CNC machining stainless steel provide parts made

directly from the customer’s 3D drawings, reducing the likelihood

of errors. Proprietary software automates toolpath generation to

decrease manufacturing times and reduce costs.

|

2-What industries use JYH services? - We serve a variety of industries including medical device,

automotive, Robot, aerospace,consumer product.

|

3-How many machines do you have? - We currently have more than 60 machines: roughly 40+ CNC mills and

30 Injection mold machine,10+ 3D printers. With our long history of

growth, this number is always changing.

|

4-How do I get a quote? - To get a quote for all of our services, simply send us your 3D CAD

model to us. You'll get an interactive quote within hours with free

design feedback. If there are problem areas in the submitted

design,we will provide free design feedback(DFM).

|

5-What types of files do you accept? - We can accept IGES (.igs), STEP (.stp), ACIS (.sat) or Parasolid

(.x_t or .x_b) format.

|

6-Do you provide First Article of Inspection (FAI) Service? - We can provide FAI as part of the unlimited offer.

|

7-What is payment term does your company can be acceptable? - We can accept T/T (50% prepayment should be paid before start the

production; the 50% remaining payment should be paid after finish

the project).

|

8-What is your lead time after we place an order with you?

Once get your order,we will sart to order review and it is usually

takes 3-6 work days,but it should be finally to the actual product

quantity, structure, post-processing. |

CNC Machining centre workshop

If you need custom machined parts with complex geometries, or get

end-use products in the shortest possible time,

JYH CNC Precision maching company is good enough to break through

all of that and achieve your idea immediately.