5 Axis CNC Machining Services For Precise Machining Handle Complex

Design Parts

Get high-precision, accuracy, intricate machined parts with

extremely complex geometries with our 5 axis

CNC machining services. Competitive pricing and fast turnaround.

Try JYH technology Now!All information are secure and confidential

by us.

Our standard tolerances for CNC machining metals are compliant with

DIN-2768-1-fine,

while for plastics parts it is DIN-2768-1-medium,standard tolerance

for a CNC machining is typically ± 0.005”.

The tightest machining tolerances possible are in the range of

±0.001”.

Parts Certifications

ISO 9001:215 | AS9100D | ITAR Registered

►Free & Automatic DFM feedback

►Tolerances down to ±0.0004″ (0.01mm)

►24/7 engineering support

5 Axis CNC Machining Facilities

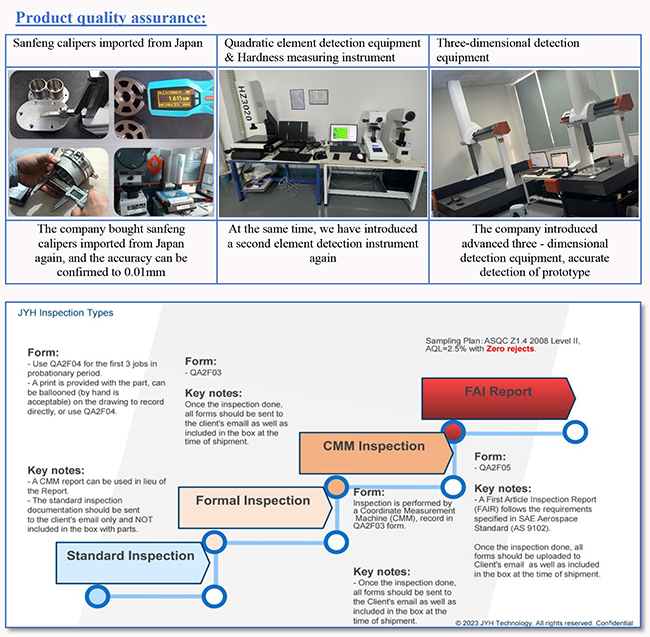

JYH implements strict quality control protocols to ensure that

every client receives superior-quality products.

We have dedicated workshops with state-of-the-art equipment for a

wide range of operations.

This way, we incorporate meticulous inspection in our 5-axis CNC

machining processes.

Tolerance for 5 Axis CNC Machining Services

Type

| Tolerance |

Linear dimension

| +/- 0.015 mm

+/- 0.002 inch

|

| Hole diameters (not reamed) | +/- 0.015 mm

+/- 0.002 inch

|

| Shaft diameters | +/- 0.015 mm

+/- 0.002 inch

|

| Part size's limit | 850 * 650 *550 mm

39.0 * 23.5 * 23.5 inch |

5 Axis CNC Machining Part Size Standards

Surface Finish Options for 5 Axis CNC Machining Services

Our part finishing services are exceptional as our teams are

experts in plastic, composite, and metal surface finishing.

Furthermore, we have state-of-the-art machines and infrastructure

to bring your idea to life.

Applications of 5 Axis Milling

Our 5-axis milling services is your best bet when it comes to

manufacturing complex, highly precise components

for a wide range of industries. Our manufacturing capabilities

allow us to accelerate the production of several components,

including:

►Automotive components: Engine housing, light guides, valves,

engine covers, inspection jigs;

►Aerospace parts: Fuselage sections, bulkheads, landing gear

components

Medical and Surgical tools: Forceps, scalpels, spacers, clamps,

cutters, surgical scissors;

►Military components: Submarine parts, turbine blades, engine

parts, weapons, sensors;

Military components: Submarine parts, turbine blades, engine parts,

weapons, sensors.

Quality Inspection

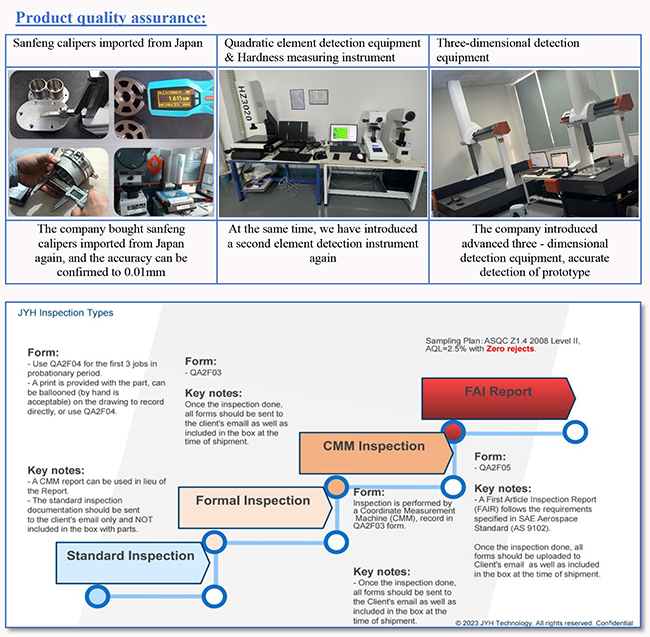

- In addition to our stringent in-process controls, all components

must pass a thorough final inspection.

we have a coordinate measuring machine, salt spray testing

machines, profile projectors and other precision

measuring devices, etc.

- Customers' CAD drawings can be directly imported in the coordinate

measuring machines (CMM) for a

direct comparison to the dimensions that are taken from the

physical part.

- All testing is conducted in a 20 degree Celsius climate-controlled

inspection room and the CMM is calibrated to

GB/T 16857.2-2006 (ISO10360-2:2001) standards. All components and

sub-assemblies are 100% inspected,

identified with a logo if required and a final inspection is

generated pertaining to all the critical dimensions.

Our workshop

Our payment method

Our shipping method

Frequently Asked Questions

► When should I choose 5-axis CNC machining?

The flexibility of 5-axis CNC machining allows the creation of

complex components with complex shapes and geometrical details.

The stability of the machining tool also gives more consistent and

smoother surface finishes.

Therefore, you should choose 5-axis machining whenever you need to

produce complex parts with tight tolerances.

► What’s the maximum part size for 5-axis CNC machining?

Our 5-axis milling machines can accommodate a length of 42 inches

bar stock.

This allows us to work on a wide range of projects for various

applications.

► How much does your CNC machining service cost?

The cost of your CNC machining projects is not fixed as it depends

on the characteristics of your project

such as the design, and tolerances. Machining times of the material

to be used in the project also contribute to this pricing.

For example, if you’re making a part that has a combined machining

and material cost of $2 and a setup cost of $200,

one part will cost $202. However, if you make 200 parts, each would

cost $3!

JYH technology, Your Professional CNC Machining Low Volume

Manufacturing Services Partner!