Custom Plastic Injection Molding Service With Short-Run Production

Medical Parts

Injection Moulding is highly repeatable; this means that all the

parts that are produced will be identical, which is especially

convenient for brand consistency and part reliability in high

volume production

Overview of Injection Molding:

Injection moulding enables complex shapes to be mass-produced with

a high level of efficiency and manageable costs. A wide selection

of materials allows engineers to exactly match the physical

properties they require for any given product. Additionally, the

application of multi-shot moulding techniques allows one to secure

an appealing visual appearance, as well as incorporating additional

functionality to the final product using materials that give high

mechanical properties. Yet, the actual process can be quite

multifarious, especially when it comes to achieving uniformity.

Injection Moulding Process:

Plastic injection moulding allows to produce large numbers of parts

with great accuracy and very quick cycle times from multi-cavity

tools. The general process of injection moulding involves a certain

amount of polymer materials being heated, melted, and injected into

a mould under high pressure. Further into the process, main

units of the injection moulding machine are:

a) feed hopper;

b) heated barrel;

c) crew (known as the injection unit);

d) clamp unit (which holds the mould together under the injection

pressures);

e) ejection unit (which removes the part from the mould).

Plastic Material Comparison Chart

Material | Approximate Tensile Strength | Impact Strength | Electrical Insulation | Temperature Resistance | Chemical Resistance | FDA Compliant | Cost (low to high) |

Acrylic (PMMA) | 8000 psi | low | no | high | strong | no | medium |

Acrylonitrile Butadiene Styrene (ABS) | 5900 psi | high | no | low | medium | no | medium |

Nylon Polyamide (PA) | 12400 psi | high | yes | high | strong | yes | high |

Polycarbonate (PC) | 9500 psi | high | no | high | weak | yes (can contain bisphenol A, or BPA) | high |

Polyethylene (PE) | 1400 psi (LDPE)

3480 – 6530 psi (HDPE)

800 – 13100 psi (PET) | high (LDPE)

high (HDPE)

low (PET) | yes | low | strong (LDPE)

strong (HDPE)

strong (PET) | yes | low |

Polyoxymethylene (POM) | 6400 – 10600 psi | high | yes | high | strong | yes | high |

Polypropylene (PP) | 4800 psi | medium | yes | medium | strong | yes | low |

Polystyrene (PS) | 2560 – 7690 psi | high | no | | medium | yes | low |

Thermoplastic Elastomer (TPE) | 290 – 8200 psi | high | no | low | strong | no | high |

The moulding process could be described by the following steps:

Thermoplastic granules are prepared according to the manufacturer’s

guidelines. In some cases, this may mean that the material is dried

in a desiccant dryer to remove moisture — if the moisture isn’t

removed it could affect mechanical properties of the component.

Once prepared, the material is poured into the hopper of the

machine;

Thermoplastic granules are prepared according to the manufacturer’s

guidelines. In some cases, this may mean that the material is dried

in a desiccant dryer to remove moisture — if the moisture isn’t

removed it could affect mechanical properties of the component.

Once prepared, the material is poured into the hopper of the

machine;- The material enters the throat of the barrel via the hopper. The

plastic granules are collected by the helix of the rotating screw —

the feeding zone of the screw;

- The barrel is heated along its length using heater bands. There are

a number of zones depending on the machine size. The zones have

different temperatures along the length of the barrel. The

temperatures are set in conjunction with the material supplier’s

specification sheet;

- The screw rotates, which moves the material forward with the

pressure and determined rotational speed towards the compression

zone. This zone of the screw is designed to put a shear heat into

the plastic and to push the material against the barrel wall,

giving it a consistent melt. As the material is pushed through, it

enters the metering zone of the screw and fills the front of the

barrel;

- Once the material is injected via the nozzle at the end of the

barrel, it enters the runner system of the mould tool;

- The runner system allows the material to flow through a gate into

the cavity of the mould tool, which forms the shape of the finished

product;

- The mould tool is held at a constant temperature, which, again, is

defined by the material’s specification sheet. Keeping the tool at

a constant temperature allows heat to be drawn from the plastic

until it reaches its heat deflection temperature (HDT). The HDT is

also defined via the material’s specification sheet;

- Once the parts have reached the HDT, they will remain in a solid

state. The mould tool can be opened;

- Once ejected, the components fall into a boss. Parts also could be

collected from the mould via a robot or a conveyor belt;

- The tool closes and the whole process repeats.

The Many Benefits of Plastic Injection Molding:

l There are a host of benefits that come from producing parts through

plastic injection molding. They include:

l Infinite variety. Virtually any shape you can think of can be

manufactured as a plastic part.

l Intricate details. The force with which plastic is injected into a

mold ensures that even the tiniest spaces are properly filled.

l Low per-piece cost. While there are upfront costs for creating the

mold, highly automated production processes result in a very low

cost per part.

l High output. Parts can be produced very quickly.

l More cost-effective than machining. While the upfront cost of

machining may, in some cases, be lower, in the long run, plastic

injection molding is much more cost-effective.

l Resource-conscious process. The injection process uses only as much

material as needed for each part, and any material left at the end

of a process can be ground up and recycled.

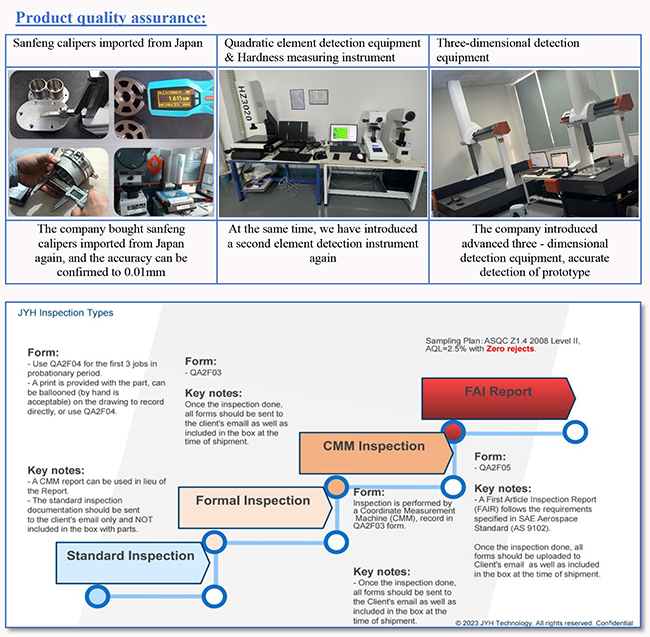

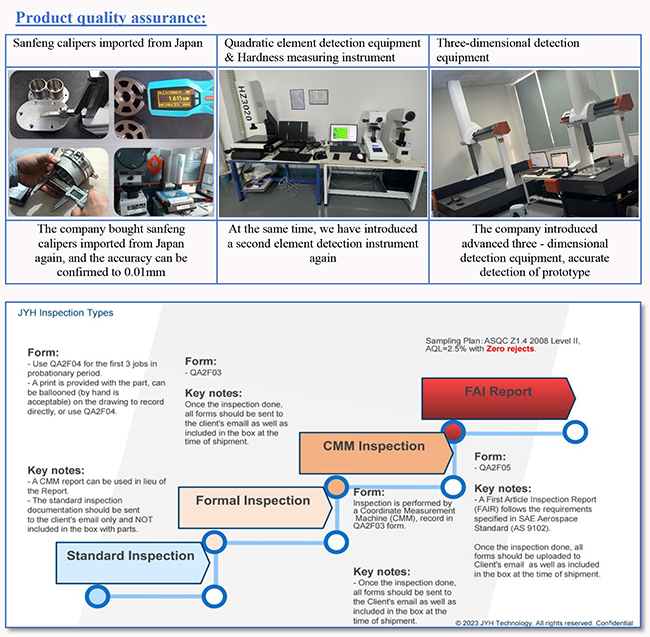

QC checking before ship the product:

Payment term:

Shipping way:

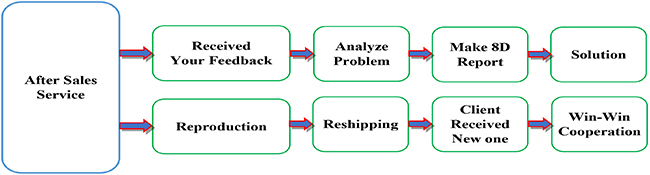

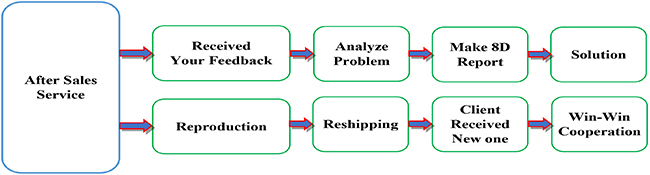

After service:

Custom Plastic Injection Molding Service With Short-Run Production

Medical Parts,JYH is your best injection mold supplier!

Injection Moulding is highly repeatable; this means that all the

parts that are produced will be identical, which is especially

convenient for brand consistency and part reliability in high

volume production.

Thermoplastic granules are prepared according to the manufacturer’s

guidelines. In some cases, this may mean that the material is dried

in a desiccant dryer to remove moisture — if the moisture isn’t

removed it could affect mechanical properties of the component.

Once prepared, the material is poured into the hopper of the

machine;

Thermoplastic granules are prepared according to the manufacturer’s

guidelines. In some cases, this may mean that the material is dried

in a desiccant dryer to remove moisture — if the moisture isn’t

removed it could affect mechanical properties of the component.

Once prepared, the material is poured into the hopper of the

machine;