Small Batch CNC Machining And Precision Machining Stainless Steel

Prototyping

Small Batch CNC Machining process

JYH CNC precision machining make custom parts on demand using over

70 materials and 15 processes.

You'll find plating (black oxide, nickel), anodizing (Type II, Type

III), and chromate coating at scale;

Tolerances down to ±0.001 in. (0.020mm); and Cost-efficient

machined parts at higher volume.

At the same time, we bought 50 sets high precision CNC machines to

expand our business in small volume high precision CNC machining.

Reduce part costs with higher quantities of machined parts At JYH

CNC precision machining company.

-Free DFM feedback in 1-2 hours

-Tolerances down to ±0.0001″

-Machined parts as fast as 1 working day

Products Description

| Name | Small Batch CNC Machining And Precision Machining Stainless Steel

Prototyping |

| Tolerance | ±0.002mm,can be communicated |

| Format files | STP, IGS,STL or X-T |

| Lead Time | 5-8 working days |

| Certificate | Material SGS files available and pass ISO9001:2015 |

Choose JYH For Your Low Volume CNC Machining

Are you looking for a low-volume CNC machining company that will

take on your small-batch production projects?

JYH is a reliable and trusted CNC manufacturer for your low-volume

production.

With top-notch machining centers and experts, our on-demand

manufacturing services include CNC milling,

turning, 3d printing, sheet metal fabrication, and injection

molding.

The Materials of Small Batch CNC Machining :

| Aluminum | Stainless steel | Steel | Copper | Plastics | Titanium |

| Aluminum 2024 | Stainless steel 304 | Steel Alloy 4130 | Brass C230 | ABS | Titanium Grade 2 |

| Aluminum 5052 | Stainless steel 303 | Steel Alloy 4140 | Brass C360 | PMMA | Titanium Grade 5 |

| Aluminum 6061 | Stainless steel 316 | Steel Alloy 1018 | Copper T2 | PEEK | |

| Aluminum 6082 | Stainless steel 15-5 | Steel Alloy 4140PH | Copper 27400 | Polycarbonate | |

| Aluminum 7075 | Stainless steel 17-4PH | Steel Alloy 4340 | Copper 2700 | Polyethylene | |

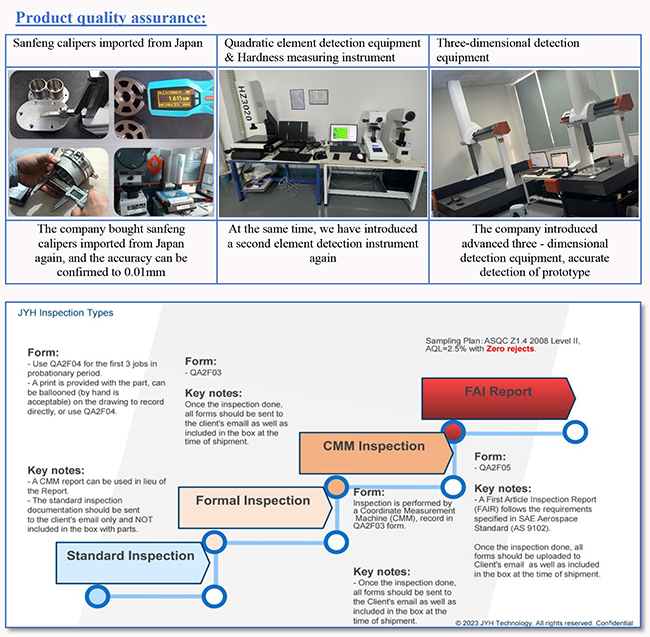

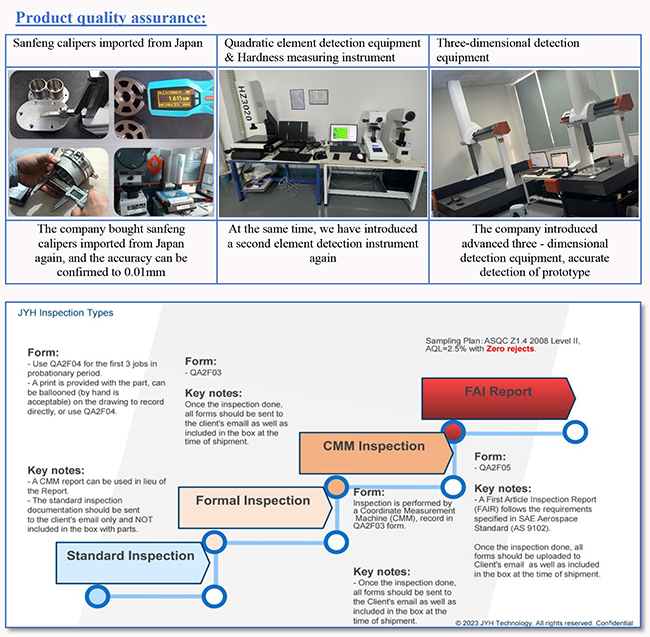

Quality Reporting

All parts are inspected for cosmetic conformance to workmanship

standards and dimensional conformance on at least three dimensions

(typically X, Y, and Z), but with production parts for machining,

we also provide conventional inspection reporting like FAIs,

Certificate of Compliance (CofC) documentation, and additional like

ISO 9001 quality certificated and AS9100 and ISO9001.

QUALITY CONTROL FOR QUALITY CNC MACHINING PRODUCTS

With Inbound Quality Inspection we test the quality of the parts

that come to us before they are used in our machines.

With In-process Quality Inspection we use state of the art lasers

to make sure every line is precise.

And with good Quality Inspection during final assembly, every

machine is comprehensively tried and tested 100% before being

shipped.

Shipping way:

Payment method:

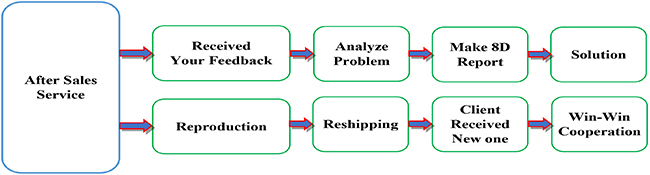

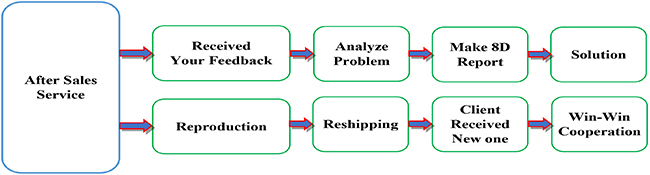

After sales service:

Our workshop:

FAQs:

- Are you a trade company or manufacturer?

We are a manufacturer with more than 15 years of experience in CNC

machining and

Small Batch CNC Machining Supplier Of Machined Prototype And

Short-Run Production.

- Can you protective my business, will my drawing be safe after you

get it?

Yes, we can sign the NDA before you send the drawing.

Yes, there is a sample charge, the sample charge can be refunded

when place the order.

- How soon can I get your quotation?

Within 1 hours or less and in nearly all cases.

- Available for customized design drawings?

Yes, CAD, STP, IGS, PDF, Solidwork, etc.

- What tolerance standards do you guarantee?

We guarantee that our manufacturing partners follow ISO 2768

standards for all CNC machined parts.

Parts machined with metal will follow ISO 2768-m (medium) or ISO

2768-f (fine).

Parts machined with plastics will follow 2768-m (medium).

Geometric tolerances down to ± 0004 in. (0.010 mm) are possible but

must be clearly indicated in technical drawings.

We can achieve tighter tolerances on shafts with up to H7 fits with

manual quoting and on occasion tighter.

- What are the minimum and maximum dimensions you can machine?

At JYH,we offer CNC milling (3-axis, 3+2-axis and 5-axis) and

turning. Milled parts can be machined up to 2000 x 1500 x 800 mm

(78.7 x 59.0 x 7.8 in.) for 3/3+2 axis CNC milling. For 5-axis

milling, the maximum part size is 650 x 650 x 300 mm (25.5 x 25.5 x

11.8 in.).

The maximum diameter for CNC turning is 431mm (17 in.), length 990

mm (39 in).

Minimum part dimensions recommended are around 0.39 x 0.39 x 0.39

in. (10 x 10 x 10mm).

The minimum for feature dimensions is 0.5 mm.

Try JYH technology Now!All information are secure and confidential

by us.

Contact us today so we bring your low-volume projects to reality.