Precise Low Volume CNC Machining Stainless Steel Parts For Medical

Parts

Low Volume Precision Short Runs Of CNC Machining Parts

CNC machining is used to control a wide range of complex machinery.

It is a computerized manufacturing process that controls

the movement of production equipment using pre-programmed software

and code.

JYH Provide Low Volume Precise Machining For Metal Stainless Steel

Meidcal Parts services In Shenzhen.

Reduce part costs with higher quantities of machined parts At JYH

CNC precision machining.

Take advantage of advanced manufacturing solutions with competitive

rates and short lead times.

You'll find plating (black oxide, nickel), anodizing (Type II, Type

III), and chromate coating at scale;

tolerances down to ±0.001 in. (0.020mm); and cost-efficient

machined parts at higher volume.

-Free & Automatic DFM feedback

-Tolerances down to ±0.0003″

-Machined parts as fast as 1-2 day

Production Capabilities for CNC Machining

Tolerances

- Shop tolerance = +/- 0.001 in.

- Able to hold +/- 0.001 in. for reamed holes (print required)

- Up to +/- 0.005 in. feature location on the same side (print

required)

Surface Roughness

- Flat and perpendicular surfaces = 60 µ in.

- Curved surfaces = 120 µ in.

Products Description

| Product Name | Low Volume Precise Machining For Metal Stainless Steel Meidcal

Parts In Shenzhen |

| Tolerance reach | ±0.005mm,can be communicated |

| Format files | We can accept native SolidWorks (.sldprt) or ProE (.prt) files as

well as solid 3D CAD models from other CAD systems output in IGES

(.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b)

format. We can also accept .stl files. Two-dimensional (2D)

drawings are not accepted. |

| Lead Time | 5-6 working days |

| Certificate | ISO9001/16949 |

Materials of Low volume machining:

| Aluminum | Stainless steel | Steel | Copper | Plastics | Titanium |

| Aluminum 2024 | Stainless steel 303 | Steel Alloy 4130 | Brass C230 | ABS | Titanium Grade 2 |

| Aluminum 5052 | Stainless steel 304 | Steel Alloy 4140 | Brass C360 | PMMA | Titanium Grade 5 |

| Aluminum 6061 | Stainless steel 316 | Steel Alloy 1018 | Copper T2 | PEEK | AZ81 |

| Aluminum 6063 | Stainless steel 416 | Steel Alloy 1215 | Copper 2800 | POM | AZ91 |

| Aluminum 6082 | Stainless steel 15-5 | Steel Alloy 4140PH | Copper 27400 | Polycarbonate | AZ80A-76 |

| Aluminum 7075 | Stainless steel 17-4PH | Steel Alloy 4340 | Copper 2700 | Polyethylene | AZ63 |

| 01 | 02 | 03 | 04 |

| JYH | Offer first article inspectionWe offer first article inspection

services for batch production. | Draft contract

We review on the project and contact customer for detail

information. | Produce sample We produce sample parts according to FAI agreement and deliver to

you. | Full-scale production The full-scale production starts and finishes production within lead time. |

| You | Request inspection

You request first article inspection for a project that meets our

FAI requirements | Sign contract

You sign the FAI agreement provided by us and agree on our Terms

and Conditions. | Receive sample You receive and examine the parts, inform us of full-scale

production may begin. | Receive products You receive your prototypes or production parts on the required lead time. |

How To Process Low-Volume Manufacturing

Our clients are concerned that low-volume manufacturing doesn’t

mean compromising quality or precision when

compared to full production manufacturing. Rest assured that when

we process lower volume orders we use

the same materials, the same equipment, and the same rigorous

quality control.

How do we do it? We’re experts in high-mix, low volume production

because our systems are optimized to be salable,

from one part to a million. That means we have a robust supply

chain of raw materials so you won’t be burdened with

minimum order volume restrictions. And we have a digital

manufacturing platform that ties all of our equipment together into

a single network. That allows us to allocate resources quickly and

efficiently between work centers in order to process

even complex orders fast.

Low volume From Prototyping to Production

JYH custom sheet low volume services are highly versatile and

applicable to a wide range of industries and purposes.

JYH custom low volume services can be used for various applications

such as mold tooling, rapid prototyping, and

custom manufacturing, and more.

Functional Prototype

Functional prototypes can be built using various materials and

manufacturing methods, depending on the

complexity and purpose of the product.Functional prototype is a

critical step in the product development process,

helping to reduce risks, refine designs, and ensure that the final

product meets user expectations.

Prototyping

Prototyping refers to a set of techniques and processes used to

quickly create prototypes of a product. These prototypes are

typically used for testing, evaluation, and iteration during the

product development cycle. Prototyping plays a crucial role in

modern product development by enabling innovation, reducing

time-to-market, and enhancing the quality and functionality of

products.JYH can produce low volume prototyping from low volume

within a short time and at a low cost.

On-Demand Production

On-demand production offers swift and flexible manufacturing

tailored to specific needs. It enables efficient production of

parts as required, minimizing inventory and lead times.From an

extensive array of material options to manufacturing and assembling

sheet metal parts, coupled with adaptable delivery methods.

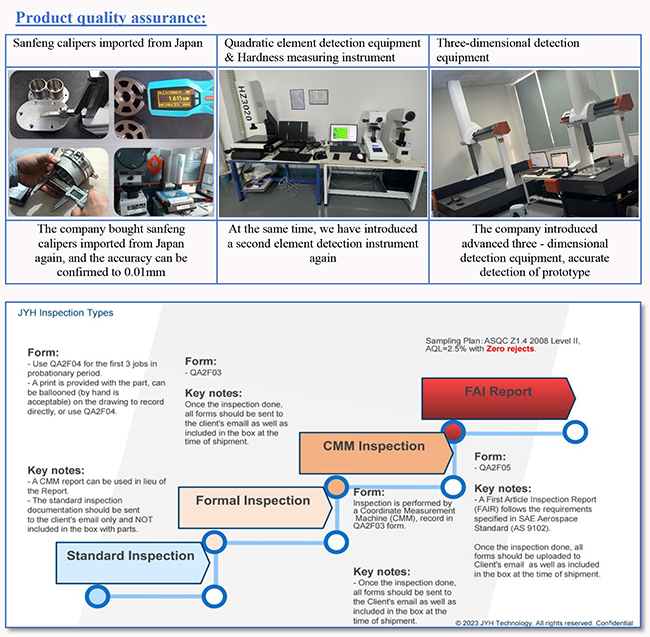

Quality Reporting

When all of your parts are machined at JYH CNC precision machining

you can be assured those parts are going to be produced in one of

our AS9100- and ITAR-certified facilities and never outsourced to

another machine shop.

All parts are inspected for cosmetic conformance to workmanship

standards and dimensional conformance on at least three dimensions

(typically X, Y, and Z), but with production parts for machining,

we also provide conventional inspection reporting like FAIs,

Certificate of Compliance (CofC) documentation, and additional

certifications like ISO 9001 and AS9100.

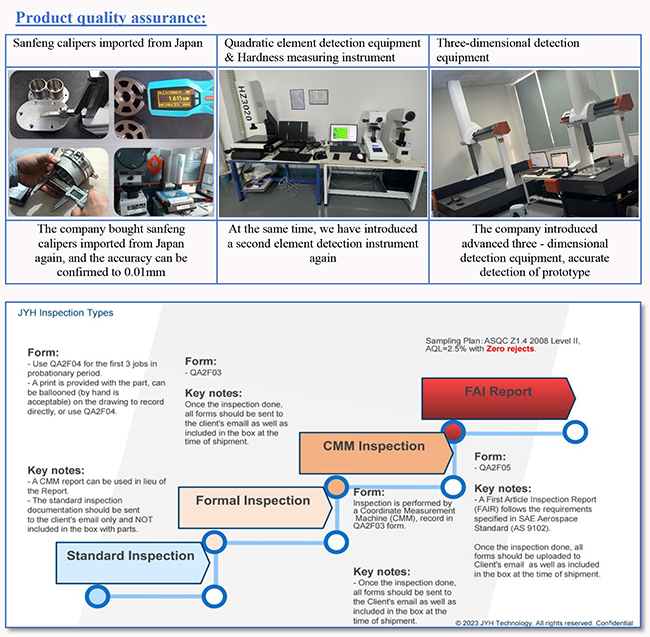

Product quality assurance:

Why choose Low Volume CNC Production:

1. Reduced Piece-Part Price with Higher Quantities

Lower your part cost when you order higher volumes of production

parts.

2. Inspection Reporting and Certifications

Get added quality assurance from conventional FAI reporting, CoC

documentation, and AS9100 certification.

3. More Finishing Options

Choose from anodizing and chromate plating for complete parts from

one supplier.

4. Supply Chain Flexibility

Avoid warehousing fees by ordering only the amount (starting at

quantity 15) you need each month.

FAQ

- Are you a trade company or manufacturer?

We are a manufacturer with more than 15 years of experience in CNC

machining and

Low Volume CNC Machining Supplier Of Machined Prototype And

Short-Run Production.

- Can you protective my business, will my drawing be safe after you

get it?

Yes, we can sign the NDA before you send the drawing.

Yes, there is a sample charge, the sample charge can be refunded

when place the order.

- How soon can I get your quotation?

Within 24-hours or less and in nearly all cases.

- What types of files do you accept?

We can accept native SolidWorks (.sldprt) or ProE (.prt) files as

well as solid 3D CAD models from other CAD systems output in IGES

(.igs), STEP (.stp), ACIS (.sat) or Parasolid (.x_t or .x_b)

format. We can also accept .stl files. Two-dimensional (2D)

drawings are not accepted.

Payment method:

Shipping way:

Try JYH technology Now!All information are secure and confidential

by us.Your Professional Low Volume Precise Machining For Metal

Stainless Steel Meidcal Parts Partner In Shenzhen!